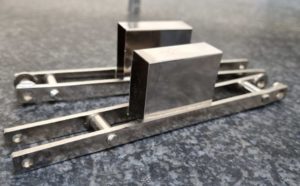

Production Process

Multi-process operation to create a bespoke corner shelving units for use in bathrooms, particularly in caravans and motorhomes

Location

Asia Manufacture

Quantity

Between 2,000 -3,000 pieces per year

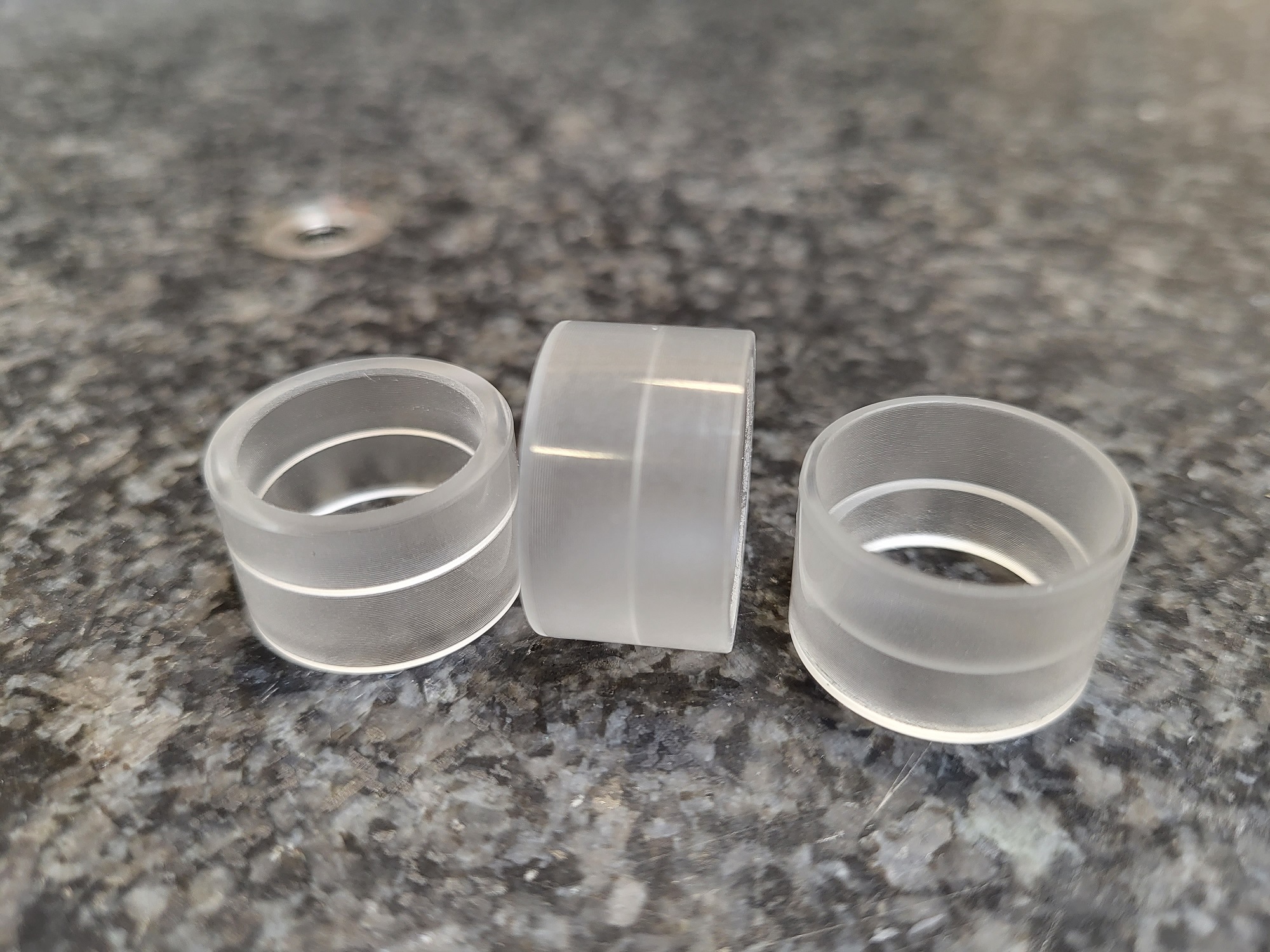

Material

Stainless Steel

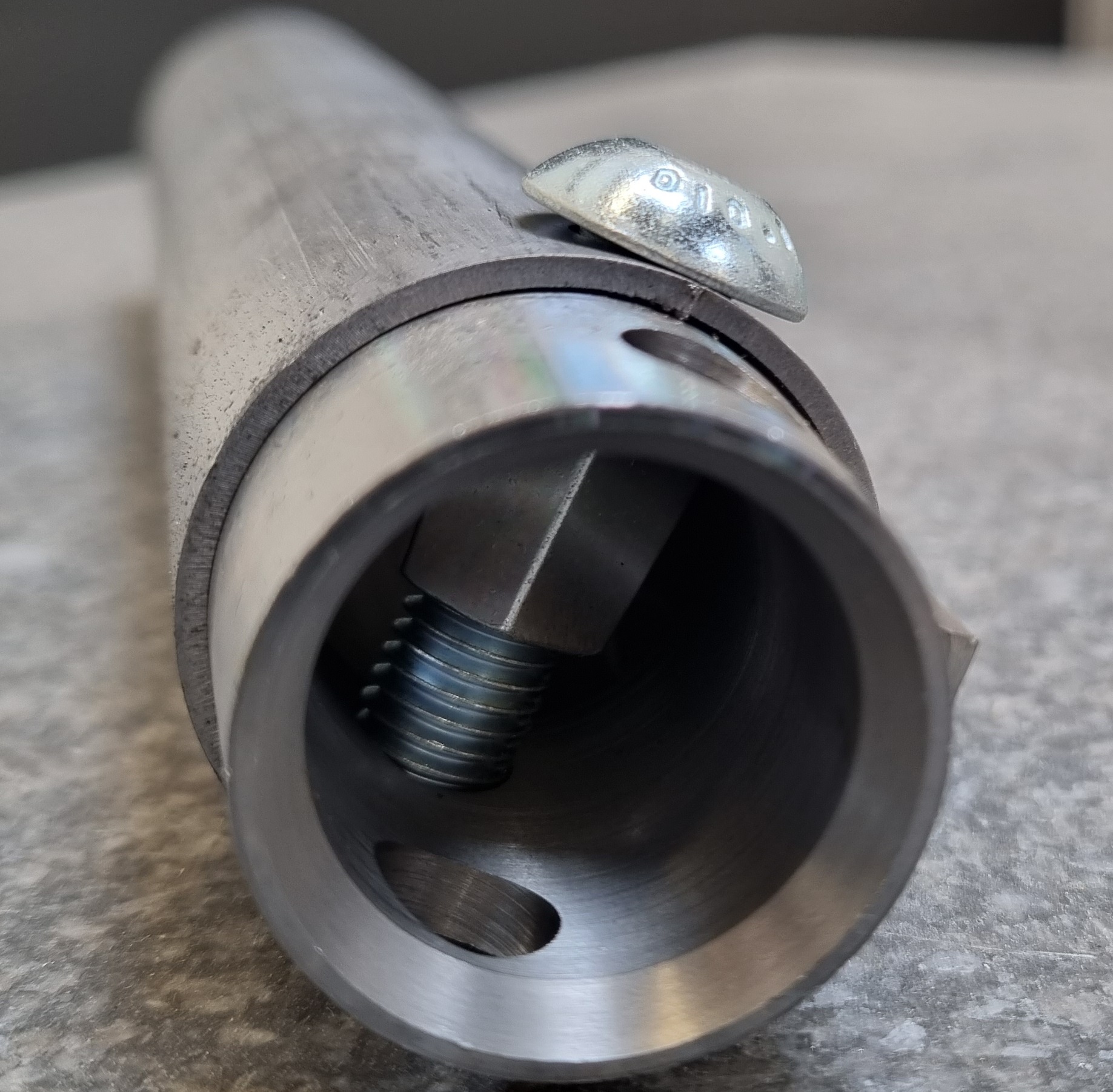

Process

Wire Forming + Bending / Welding / Plating

Quality

Random Sample Inspection

Delivery

Delivered to customer’s call-off schedule