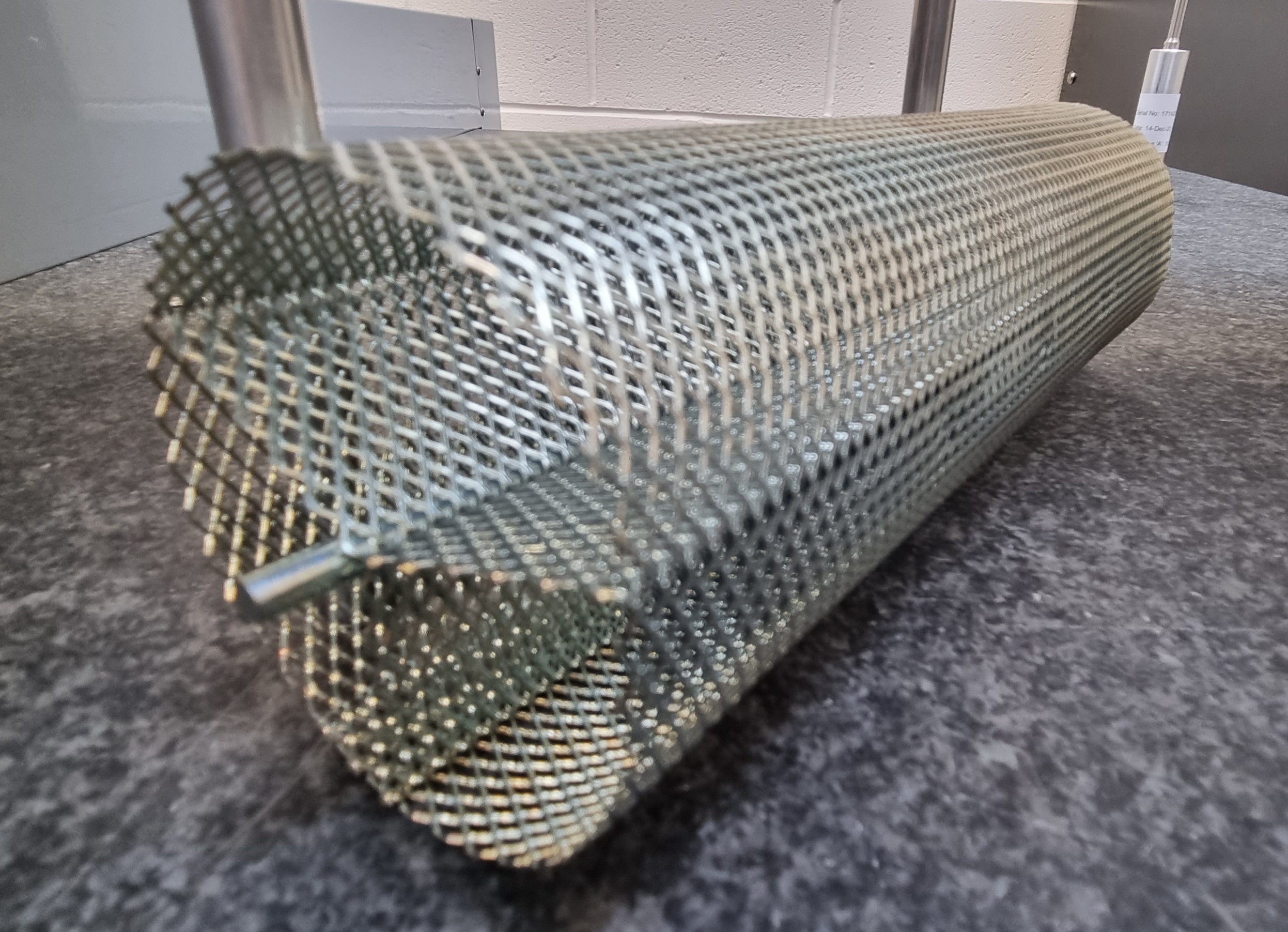

Production Process

Multi-process operation to create a bespoke pipe and nut assembly used as part of spares kits for domestic boiler repairs

Location

Asia Manufacture

Quantity

80,000 pieces per year

Material

Copper

Plastic

Process

Injection Moulding / Tube Forming / Assembled

Quality

Random Sample Inspection

Delivery

Delivered to customer’s monthly schedule