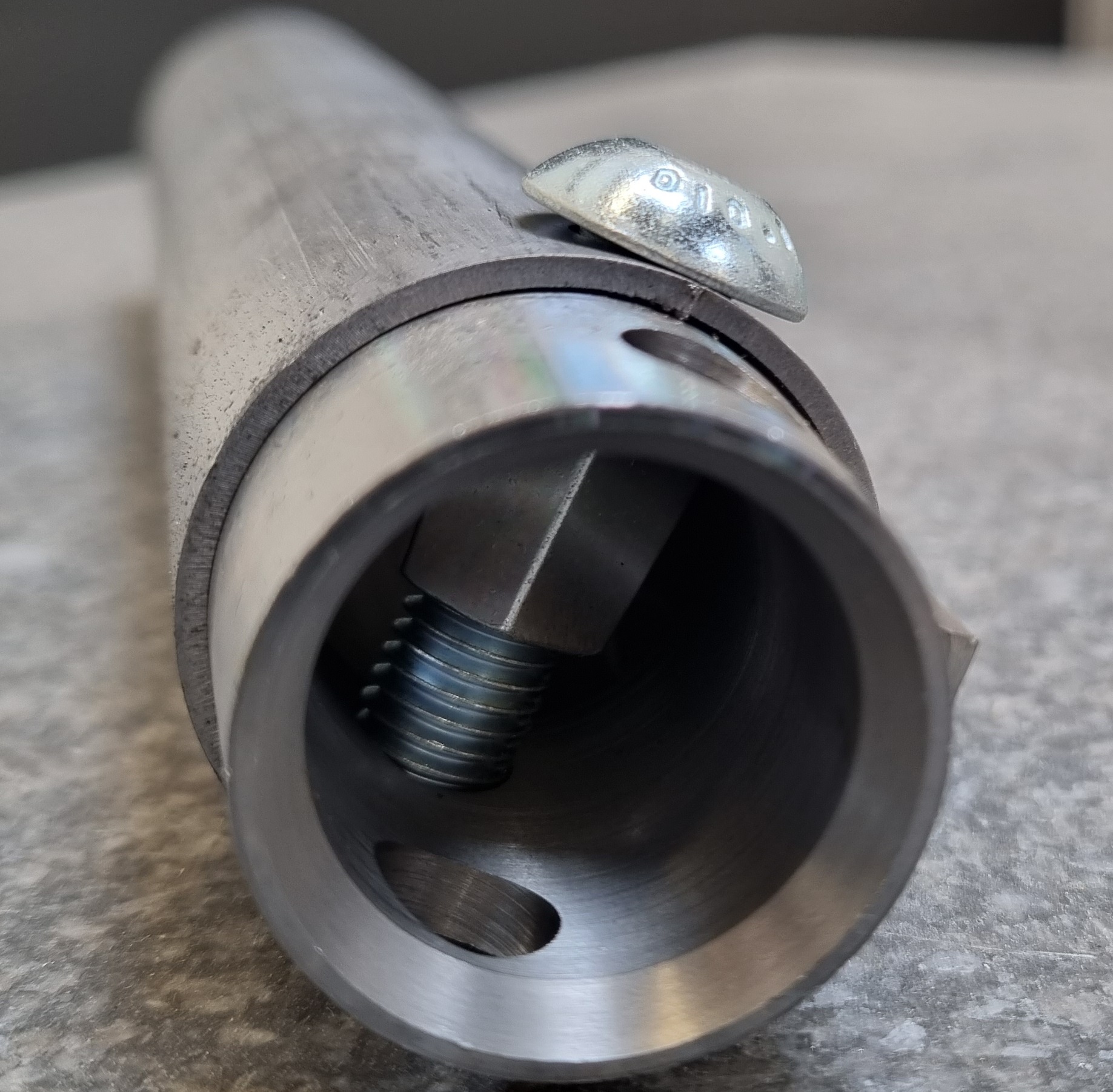

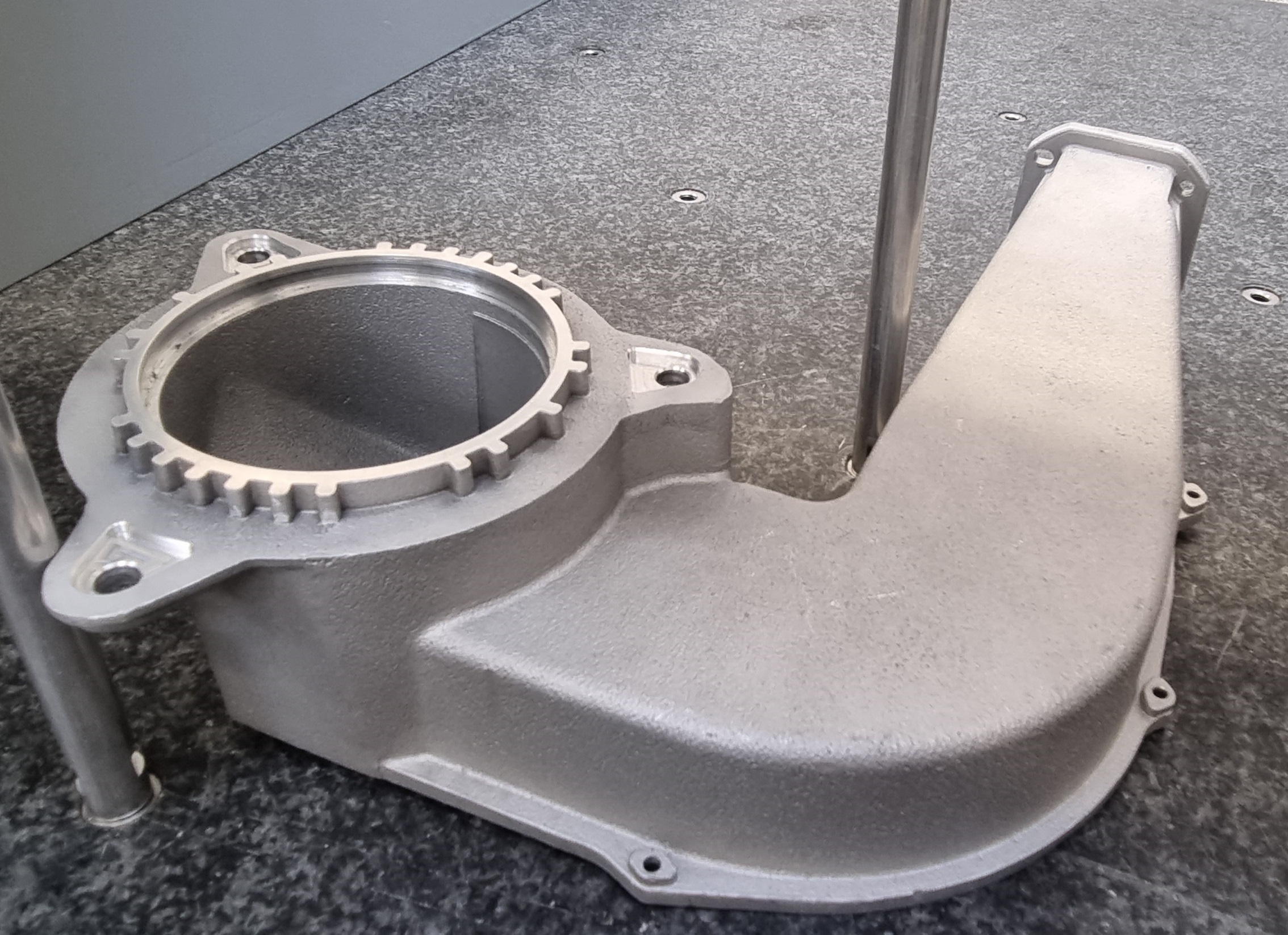

Production Process

Multi-process operation to create a loading tube, used to help with the installation of stairlifts in the healthcare industry

Location

UK Manufacture

Quantity

3,600 pieces per year (across 2 size variants)

Material

Mild Steel

Process

Laser Cut Tube / Welding / Nut + Bolt Assembled

Quality

Random Sample Inspection

Delivery

Delivered to customer’s KANBAN schedule